Recently, the UK government reaffirmed its commitment to building more homes, as well as working to reshape the nation’s economy. In this article, Andrew Carpenter, Chief Executive of the Structural Timber Association (STA) explains that whilst advancing this agenda, those involved in the process must also respect an existing commitment to achieving Net Zero emissions by 2050. Andrew goes on to detail how recent publications, such as the ‘Government Response to the Housing, Communities and Local Government Select Committee Report on the Long-term Delivery of Social and Affordable Rented Housing’, identify how both of these goals can be achieved more easily through a greater commitment to modern methods of construction (MMC).

In its new report, Homes England identifies the potential for MMC to be “significantly more productive than traditional building methods; allowing homes to be built more quickly, addressing labour and skills shortages and improving the quality, consistency and energy efficiency of newly built homes.” As an organisation at the forefront of promoting MMC amongst the sector, we have long recognised the potential of these significant benefits. In particular, we believe that timber frame and structural insulated panel (SIP) construction offer the most accessible options.

During the last few years, both MMC techniques have emerged as standout options in the housebuilding sector. The innovative building approaches enable the rapid construction of homes, whilst also delivering exceptional performance in terms of thermal and energy efficiency. Likewise, both techniques have strong environmental credentials, which makes them ideal in helping the UK to hit its target of net zero carbon emissions by 2050. Currently, the construction sector contributes around 38% of Britain’s total carbon dioxide emissions, so making this change could have a big impact.

For example, thanks to its inherent airtight and highly insulated construction, SIPs buildings are able to significantly reduce energy usage within a home. When considered alongside the UK’s commitment to building 300,000 new homes per year, it’s easy to see how important this MMC could be in helping to reduce overall carbon consumption across the nation. Of course, a significant reduction in energy usage isn’t only beneficial for the broader environment, but will also help homeowners to reduce the money they spend each month on bills.

Similarly, timber frame construction also offers housebuilders and developers a simple way to build long-lasting, durable homes in a sustainable manner. For context, concrete is currently responsible for between four to eight per cent of the world’s total carbon dioxide emissions. Therefore, any new techniques that are able to reduce usage of the material must be seriously considered.

Another benefit of timber frame construction is that it offers an effective way to sequester carbon dioxide out of the atmosphere. During its life, timber consumes carbon dioxide from the atmosphere. This embodied carbon will remain stored in the timber, even when the material is processed for use within buildings. As more timber forests are planted to support the use of timber across industries, such as construction, more carbon is subsequently captured and removed from the atmosphere. As such, pushing for the further adoption of structural timber construction ranks amongst the most sustainable options available to the sector.

Of course, it’s still important for homes built via MMC to deliver in other areas, aside from their exceptional environmental performance. Thankfully, as the report from Homes England identifies, such solutions can also enable a more rapid construction process, which could prove invaluable as the nation looks to tackle its current housing shortage. Additionally, certain techniques, such as SIPS and timber frame construction are ideal in creating homes with excellent levels of thermal and energy efficiency. This outstanding performance is due to the volumes of insulation provided as part of the structure.

Right now, Homes England is monitoring the construction of around 1,800 developments across the country, via various means of MMC production. Once completed, the organisation will have long-term, in-depth and verifiable data regarding the different available methods. At the STA, we’re awaiting the findings with bated breath, but feel confident that those methods commonly adopted for housing by our members, most notably SPS and timber frame construction, will emerge as the standout choices. Until then, we will continue to support those promoting such techniques in the best ways we can and help the industry as it moves forward into a new era of building practices.

To read Homes England’s new report, please visit: https://www.gov.uk/government/news/homes-englands-mmc-research-study-takes-shape

To find out more about the Structural Timber Association please visit www.structuraltimber.co.uk

An opportunity missed

Despite concerted efforts from industry action groups and commentators to draw attention to shortcomings in the proposals, the Government’s response to the Future Homes Standard consultation has fallen woefully below that which is required to enact real change in the journey to Net Zero, argues Andrew Carpenter from the Structural Timber Association (STA).

First and foremost, the fact that embodied carbon is not mentioned once in the entire 114-page document, is a glaring omission that represents a significant missed opportunity to reduce the overall carbon consumption of the housebuilding industry. With the Government still insisting that it hopes to build 300,000 new homes each year, reducing the upfront carbon emissions generated by the materials manufacture of these projects would have a meaningful impact on the total carbon footprint.

Instead, the response focuses on building services and prioritises the use of low carbon energy sources. However, we firmly believe that this is a back-to-front approach, as operational CO2 emissions account for only a small portion of a home’s overall carbon cost. A much more logical tactic would be to shrink the overall carbon footprint, by reducing both the embodied carbon within the construction materials and the energy consumption in use, through significant building fabric improvements. After all, switching to low carbon energy sources is of little value to homeowners if they’re still required to pay extortionate sums for the same amount of ‘clean’ energy – building homes that are engineered to use less energy in the first place is a simpler way of lifting future generations out of fuel poverty.

What’s more, the move comes in spite of industry consensus towards an embodied carbon approach, as set out by the signatories of an open letter to Robert Jenrick, Secretary of State for Housing, Communities & Local Government. Orchestrated by ACAN (Architects! Climate Action Network), the letter calls for embodied carbon to be given due consideration, pointing to the significant contribution it will make to the carbon emissions of future homes.

Signed by more than 700 prominent members of the architectural community, it states: “The carbon emissions associated with a building’s use only make up a percentage of its total carbon footprint, with embodied carbon (the emissions associated with materials, construction and refurbishments) making up an ever greater share. Embodied carbon needs to be measured and declared as well. This is known as a ‘Whole Life Carbon’ approach to construction and should be applied to all construction projects to represent their true carbon cost.”

While it’s encouraging to see that the Government has taken steps to ensure new homes will no longer be reliant on fossil fuels and has listened to some of the feedback from industry – such as retaining the Fabric Energy Efficiency Standard (FEES) – the lack of regulatory incentives for reducing embodied carbon has the potential to de-rail carbon reduction efforts, by masking the true cost of new housing developments from a CO2 perspective.

By encouraging wider use of lower carbon building materials – such as incentivising a timber-first approach – the Government could take advantage of the ‘low hanging fruit’ by reducing the overall carbon expenditure of new homes from the very outset. As well as being a renewable material, timber provides an effective carbon store, particularly when used on an industrial scale. This is because as trees grow, they trap and store carbon dioxide, removing it from the wider atmosphere – indeed, timber absorbs more carbon during its growth than is emitted during processing and installation.

It’s bewildering to us at the STA that, in the face of such industry agreement, the Government has not seized this opportunity to set the housebuilding sector firmly on the right trajectory to achieve Net Zero by 2050. That is why, in the light of the omissions from the Future Homes Standard, we emplore the Government to reconsider its stance.

We believe it’s more vital than ever to highlight the importance of embodied carbon and to demonstrate the value of using low-carbon, structural timber. What’s more, it’s crucial that the housebuilding industry recognises that it is not obliged to follow this outdated line of travel and that, as long as regulatory requirements are met, it is able to carve its own path towards delivering better quality and greener housing. After all, why wait until Government thinking catches up when timber solutions are ready now, offering a quicker, more reliable and more sustainable solution to the climate crisis?

To find out more about becoming a member of the STA or working with one of our accredited organisations, please visit: www.structuraltimber.co.uk

Timber industry to make its case at COP26

In our latest Time for Timber podcast, Andrew Carpenter, Chief Executive of the Structural Timber Association, sat down with Paul Brannen, Director Public Affairs CEI-Bois & EOS, to discuss the most important event happening in 2021, COP26.

What is COP26?

The 26th Conference of the Parties, or COP26, will see the leaders of the world converge to decide how best to tackle the global crisis of climate change. For these leaders, whom have supreme decision-making capabilities, finding and agreeing upon the necessary solutions to combat this threat at COP26 are crucial to turning the tides back in our favour. Meetings between leaders are frequent but once every four years, one nation hosts a larger conference spanning two weeks. For COP26, this responsibility falls to the UK, with Glasgow hosting the event commencing on November 1st and finishing on November 12th. Since the previous major Conference of the Parties, hosted by France in 2016, the targets set have not been met, making it ever the more vital that solutions are found in Glasgow.

What is the Timber industry hoping to achieve at COP26?

Regarding sources of carbon emissions, the construction sector is responsible for anywhere between 40 and 50 percent. During their conversation, Paul Brannen highlights that it is therefore the duty of the construction industry to reduce that figure, whilst expressing his belief that timber provides the key means in which to do this. Paul discusses what he calls the three S’s, those being sequestrate, store and substitute. As a tree grows, carbon within the atmosphere is captured within the tree itself, this process is known as carbon sequestration. Once a tree is felled and processed into building materials, the sequestered carbon remains stored within the wood. The production of building materials such as cement and steel are particularly high emitters of carbon, by substituting them with timber, the environmental impact of construction is immediately lessened. These are the core messages that Paul wishes to present to the politicians attending COP26. As he states, utilising timber within construction is low hanging fruit.

How are those campaigning for timber planning to grab the attention?

As Paul explains in his conversation with Andrew, COP events are a political conference and a trade exhibition hybrid. An allocated area of the event known as the ‘green zone’ offers organisations and associations an opportunity to literally set up stall, and promote themselves to politicians, journalists and general visitors. Collectively the timber industry, at a global level, have placed their bid to the British Government, expressing their desire for a space at COP26. However, as Paul details, the timber industry has big plans on how they intend to showcase what they have to offer. Currently, plans for a purpose-built timber pavilion are being put together by a well-known British architect. The aim is to incorporate various engineered timber products within its design, to demonstrate the vast number of applications that timber possesses as a building material. The belief is that this visually stunning centrepiece will draw politicians and visitors in, so that they can be educated and informed about the structural solution to climate change that is timber.

As Paul draws his input to the conversation with Andrew to a close, he says: “We have to remind ourselves that everyday hundreds of people come to this issue completely new, and they’re the people we need to think about first and foremost”. COP26 presents a fantastic opportunity for the timber industry to showcase, to the leaders of the world, the vast environmental benefits it has to offer. Why wait, the time for timber is now. To hear the entirety of Paul’s and Andrew’s discussion about COP26, you can find the full podcast here.

The Structural Timber Association has recently published an insurance industry guide to mass timber in the UK. The purpose of this paper is to provide the reader with sufficient information to better understand the use of timber in construction from a risk management perspective.

This document has been broken down into six main sections: Management of structural timber projects, Risk management, Compliance, Structural timber and the built environment, Building Safety Bill 2020, STA technical document library. We’ll be covering each topic in turn on this website.

STA technical document library

The STA strive to provide the most up-to-date information and technical guidance and our online library contains over 140 documents including product papers, advice notes and technical bulletins.

This library contains a wealth of information on Building Regulations and best practice principles. It is a valuable resource which can assist architects, engineers and clients who are considering specifying structural timber for projects or provide technical support during installation on site.

Published by the Royal Institute of British Architects (RIBA), the Plan of Work is split into several key project stages, which provides a shared framework for design and construction that offers both a process map and a management tool. Download the full plan here.

A blueprint to improve competence for those working on higher-risk buildings, the work was initiated by the recommendations in Dame Judith Hackitt’s review Building a Safer Future. Download full document here.

STA INSURER RESOURCES

A section of the STA website created to service the specific needs of the insurance industry, concerning structural timber systems. Insurers can download guidance and technical documents here.

STA FIRE SAFETY RESEARCH DOCUMENTS

Access to the STA’s fire test research and cavity barrier/fire stopping best-practice documentation here.

The Structural Timber Association’s insurance industry guide to mass timber in the UK can be downloaded here.

The Structural Timber Association has recently published an insurance industry guide to mass timber in the UK. The purpose of this paper is to provide the reader with sufficient information to better understand the use of timber in construction from a risk management perspective.

This document has been broken down into six main sections: Management of structural timber projects, Risk management, Compliance, Structural timber and the built environment, Building Safety Bill 2020, STA technical document library. We’ll be covering each topic in turn on this website.

5. Building Safety Bill 2020

The Building Safety Bill is a new piece of UK Government legislation aimed at reforming the regulations surrounding the safety of high-rise buildings in the UK. A major part of the UK Government’s response to the Grenfell Tower tragedy, it is currently being scrutinised in draft form, but is expected to be brought to Parliament and be passed into legislation early 2021.

Extracted from the Building Safety Bill, the following statement makes clear the need for the construction supply chain to be able to demonstrate competency. STA Assure is at the heart of the delivery of quality structural timber systems.

Clause 6: Facilitating improvement in competence of industry and building inspectors

EFFECT

160 Clause 6 states that the Building Safety Regulator must provide assistance and encouragement to persons in the built environment industry and to registered building inspectors to facilitate improvement of competence of organisations and individuals in the industry, or members of the profession.

BACKGROUND

161 This is a new provision. The independent review recognised competence as an area where improvement was needed across the built environment sector.

A working example of this clause is provided in the Bill’s accompanying explanatory notes:

Example: Functions in relation to industry competence

Under this duty the Building Safety Regulator may undertake activities such as setting the strategic direction of the competence committee (see Clause 10) to increase competence within the built environment industry, carrying out research and analysis, convening working groups, developing a communications strategy and other activities which support this duty.

For example, the Building Safety Regulator may use the insights it gains into the competence levels within the built environment industry to focus the Committee’s activities on areas where additional work is most needed and can have the most impact.

The Building Safety Regulator can also develop and implement a communications plan with the industry competence committee to encourage industry’s use of the competence frameworks and to highlight the legal requirements regarding competence.

The Building Safety Regulator may work with the competence committee to share its insights from reviewing Gateway two applications containing evidence of the competence of the Principal Contractor and Principal Designer, to improve the guidance to industry.

The Structural Timber Association’s insurance industry guide to mass timber in the UK can be downloaded here.

A wise man once said that

a lie can travel half-way around the world while the truth is still putting on its shoes.

Unfortunately, that statement has never been more relevant than it is today. From politics to pop culture, the world has become well accustomed with the perils of fake news and the ease with which it can spread. Sadly, the same thing is happening within the construction sector, where structural timber suffers from a number of harmful misconceptions about its practical suitability. In this blog, Andrew Carpenter, Chief Executive of the Structural Timber Association, looks to examine some of these misunderstandings and dispel any falsehoods that could be holding the material back from more wide-scale adoption.

THE CLAIM:

Timber is unsustainable and hurts the Amazon rainforest!

THE TRUTH:

Structural timber solutions used in the British construction sector are almost entirely sourced from well-managed forests in either Scandinavia, or in the UK itself. As such, any concern about potential damage to the Amazon Rainforest is severely misplaced. In fact, when sourced responsibly, timber is undoubtedly one of the most environmentally friendly materials currently available. Not only does it provide an effective carbon sink, but it’s entirely renewable and can be continually grown year-round.

THE CLAIM:

Timber is dangerous because it burns!

THE TRUTH:

Whilst it’s right to say that timber burns, it’s wrong to say that this alone makes the building material inherently dangerous. As with many things in construction, the safety of structural timber solutions relies on installers ensuring that proper precautions and installation practices are being followed. In well-designed buildings, structural timber solutions are enclosed with non-combustible products to reduce the likelihood of fire spread. Ultimately, good design helps to mitigate most of the associated risk and can be achieved by employing installers who work to competency schemes, such as the STA Assure scheme.

The same applies to timber battens, which are often used in cavity walls to prevent the spread of fire in the event of a blaze. When fixed in accordance with well-established structural timber protocols, such solutions are able to provide long-lasting, durable performance, which both home and business owners can rely on. To this end, when installed correctly, timber in a cavity isn’t exposed to moisture and as such, will not warp over time and create gaps that could ultimately render the battens useless.

THE CLAIM:

I can’t get a mortgage or an insurance agreement for a timber frame house!

THE TRUTH:

Once again, this statement is simply incorrect. However, it’s fair to say that the insurance industry has responded with caution to the Grenfell Tower tragedy and that, whilst Grenfell was a concrete structure, timber frame buildings have been unfairly caught in the crosshairs during this process. Yet insurance options for the material still exist. What’s more, new test data is helping to better inform those creating insurance policies about the material and how it performs in a blaze, with more and more insurance firms starting to adjust their positions.

Similarly, some mortgage providers have been incorrectly influenced by the Royal Institution of Chartered Surveyors and a form entitled EWS-1. Originally, the form was designed to address combustible cladding materials in tall buildings but has been wrongly interpreted as applying to all buildings and all materials. Fortunately, the form is currently being reviewed and its scope should soon be curtailed. Despite all this, there still remains plenty of providers who are more than happy to offer mortgage products for timber frame structures at no premium.

THE CLAIM:

Timber is not as strong as brick and can rot without you knowing!

THE TRUTH:

A common misconception amongst individuals with minimal structural timber knowledge is that the material is used to build entire homes. In fact, most timber frame houses are clad in brick. As such, concerns about the relative strength of brick and structural timber are normally misguided and not applicable in practice. With that said, there’s now also decades of evidence to support the notion that timber frame homes can be constructed without the need for brick and still go on to achieve no movement issues.

It’s a similar story when it comes to concerns around rotting. In practice, the risk of rot in structural timber solutions is wholly dependent on the quality of installation. Suffering from rot is certainly not a risk inherent to structural timber solutions and can happen to most commonly used building materials. As always, it’s essential to only work with a recognised, high-quality structural timber installer, such as those included on the STA Assure Scheme. In doing so, those looking to use the material can benefit from years of reliable performance.

THE CLAIM:

Timber is too expensive to build and then often costs more to heat!

THE TRUTH:

At the STA, we tend to hear this one a lot and aren’t really sure why people continue to believe it. However, for conclusive evidence, we can look to the first independent construction cost comparison report on timber and masonry for affordable housing, conducted in 2018 by leading cost management organisation, Rider Levett Bucknall. The results were clear, timber frame construction is more economical than masonry construction and the build programme is shorter.

It’s a similar story when assessing how much it costs to heat a structural timber home. Some people think timber has no thermal mass but it does, and it comes from the plasterboard. Additionally, it’s wrong to believe that materials with low thermal mass cause heat loss. In fact, heat loss is affected by insulation, which provides the resistance needed to prevent it. What’s more, buildings that actually do have high thermal mass levels, such as masonry structures, tend to cost more to heat as the fabric of the building absorbs heat in the early stages impacting on comfort levels.

THE CLAIM:

There’s nobody in my region who knows how to build with timber!

THE TRUTH:

Nobody is in a better position to tell you this isn’t true than the STA! We know more than anyone that timber frame installers exist all around the country and that there’s no regional variation with regard to competency or quality. Whether it’s using one of our member organisations, or those recommended through our STA Assure Scheme, individuals wanting to use structural timber frame construction can rest easy in the knowledge that reliable and affordable installers are waiting and ready to work with them.

For more information, please visit: www.structuraltimber.co.uk/members

The Structural Timber Association has recently published an insurance industry guide to mass timber in the UK. The purpose of this paper is to provide the reader with sufficient information to better understand the use of timber in construction from a risk management perspective.

This document has been broken down into six main sections: Management of structural timber projects, Risk management, Compliance, Structural timber and the built environment, Building Safety Bill 2020, STA technical document library. We’ll be covering each topic in turn on this website.

4. Structural timber and the built environment

Timber, as part of the circular economy, is the safest and most effective carbon store.

Currently, the construction industry represents around 10% of total UK carbon emissions and directly contributes to a further 47%. As a result, the industry finds itself in a position of great responsibility and influence with regards to the nation’s climate change efforts.

As trees grow, they naturally absorb carbon, which continues to be stored when the material is transformed into structural timber products. Timber absorbs and stores more carbon than it emits during processing and installation.

Engineered timber solutions act as an effective carbon store when used as part of a building. When the building has reached the end of its use, this stored carbon can either be re-used as fuel or will naturally filter back into the soil. By comparison, the use of concrete and steel within construction leads to considerably more energy and carbon usage.

To this end, a report published by Chatham House (Making Concrete Change: June 2018) shows that cement is the source of 4-8% of total global carbon dioxide emissions. Whereas more carbon dioxide is absorbed and stored within timber products than is emitted during its harvesting process, manufacturing and transportation combined.

When used instead of other building materials, a single cubic metre of timber will save around 0.8 tonnes of carbon dioxide emissions. With such strong green credentials, it’s clear to see why so many organisations are embracing timber. Not only does the material provide strength and aesthetic beauty, it also offers an effective solution in battling climate change.

Timber is an organic, natural material; wood can breathe and maintain a comfortable and healthy indoor climate. Recognising this, the French government recently announced new sustainability legislation to help make the country carbon-neutral by 2050. The new law, enforceable in 2022, states all new public buildings in France are built from at least 50% timber, or other natural materials.

Health and wellbeing is front and centre for many large corporations, such as Google, in trying to attract and keep the best staff in the industry.

The use of timber in construction is known to have numerous positive effects on health, proven in various studies. People working in environments with more wood are observed to show lowered heartbeat rates, a decreased perception of stress, decreased blood pressure and increased interaction. A closer connection to such a natural material can only help to promote a sense of wellbeing. In creating such environments, which employees clearly favour – and an increasing number of studies point to those workplaces being more productive, with lower rates of absenteeism and sickness.

The Structural Timber Association’s insurance industry guide to mass timber in the UK can be downloaded here.

“Of all the things we build today, good school buildings are the most important,”

says Laila Owren, principal at Nordre Ål school, in Lillehammer, Norway. She’s seen first-hand how keenly aware the younger generation is of environmental issues and knows how important it is to reflect that social awareness in their learning spaces.

Schools made of wood play an important role in #BuildingABetterFuture, are environmentally friendly and have a positive effect on students’ health and wellbeing. Nordre Ål school and Torvbråten school are inspiring examples of renewable learning environments for the next generation, harnessing sustainable timber solutions for the good of the planet.

This video was produced for Stora Enso by BBC StoryWorks, the commercial content division of BBC Global News.

The Structural Timber Association has recently published an insurance industry guide to mass timber in the UK. The purpose of this paper is to provide the reader with sufficient information to better understand the use of timber in construction from a risk management perspective.

This document has been broken down into six main sections: Management of structural timber projects, Risk management, Compliance, Structural timber and the built environment, Building Safety Bill 2020, STA technical document library. We’ll be covering each topic in turn on this website.

3. Compliance

Product testing for fire resilience is a key activity of the STA and its timber system manufacturing members. As an Association, the STA has taken the unprecedented step of completing a significant number of fire resilience tests on timber frame systems to EN 13165. Carried out by UKAS accredited laboratories, the tests provide the market with empirical data on the performance of systems, relating to buildings in use, and confirms they are all a safe building method.

The decision to test to European EN standards and not British Standards is consistent with the STA strategy to ‘raise the bar’ in terms of exceeding the regulatory requirements for performance and to build-in additional fire resilience.

The output from this programme is a series of STA Pattern Books and guidance notes to provide designers and engineers with hard data on performance-tested structural timber systems, which has been peer-reviewed by subject matter experts from the Building Research Establishment at Watford.

In addition to the STA’s fire resilience tests, a significant amount of data was gained from member’s own test programmes; the results of which will be collated in additional volumes of research data to be released early 2021.

Ongoing fire testing is still a key feature of STA activity, including comprehensive research into mass timber systems.

It is important to recognise that the structural timber market is separated into two distinct risk profiles:

- Low and medium rise buildings

- High rise and complex buildings

In both cases, the principal risks are broadly the same, but the mitigation strategies will differ. Typical examples of this relate to regulatory requirement on the preservation of life as determined by Building Regulations. Single occupancy buildings are expected to be clear of occupants within 30 minutes, whereas for multiple occupancy is 60 minutes.

In most cases, structural timber relies on non-combustible protection for fire resilience, utilising products such as plasterboard, which has been common practice for many years. More complex buildings designed to feature timber as the internal finish will require different mitigation strategies, which will be defined by specialist fire engineers.

STA members are fully conversant with the regulatory requirement for differing styles of buildings and are committed to regulatory compliance and the provision of empirical proof; including the installation of fire stopping products designed to limit the spread of fire within the building structure.

Resilience to moisture ingress and fire compartmentalisation centres around good design. In both cases and regardless of construction type, designers are specifically aware of the need to ensure buildings are designed to minimise the risk of fire spread and water damage. Building Regulation by means of Approved Documents addresses many of the issues in a generic form, with members relying on guidance notes from STA to provide specific details for structural timber. These issues are addressed within the STA competency programme to ensure that designers and engineers are aware of their responsibility to prevent fire spread and moisture ingress.

Equally, a feature of good design is to allow remediation of a building that has suffered damage from either fire or water. Depending on the extent of the damage, sections of a well-designed building can be replaced avoiding a total loss scenario.

The Structural Timber Association’s insurance industry guide to mass timber in the UK can be downloaded here.

The Structural Timber Association has recently published an insurance industry guide to mass timber in the UK. The purpose of this paper is to provide the reader with sufficient information to better understand the use of timber in construction from a risk management perspective.

This document has been broken down into six main sections: Management of structural timber projects, Risk management, Compliance, Structural timber and the built environment, Building Safety Bill 2020, STA technical document library. We’ll be covering each topic in turn on this website.

2. Risk management

The STA has long recognised the increased risks associated with the use of engineered timber solutions. Focus is predominantly around fire resilience and water ingress, both during construction and in use. The Association has committed its members to a quality, compliance and competency programme for many years to mitigate those risks and to engender a best practice culture.

The STA Assure programme pre-dates the Dame Judith Hackitt review undertaken by the Government following the Grenfell Tower tragedy of June 2017. It responds well to the concerns expressed at the time in relation to the construction industry’s ability to confirm competency and compliance.

There are three key pillars of activity driving quality assurance within the membership of STA, which broadly align with the new Building a Safer Future, initiated by Dame Judith Hackitt and crafted by the Competence Steering Group 2020 of the Construction Industry Council (CIC):

- Competency

- Training

- Site Safe policy

The Hackitt Review highlighted the need for the construction industry to rely on actual tested data in establishing the suitability of building products in use and not the use of extrapolated data often referred to as desktop studies. Responding to this, STA commissioned extensive product testing described in the compliance section of this paper.

Competency

STA Assure is the Association’s membership and quality standards scheme. Designed to benefit both clients and members, it offers reassurances by promoting the differing accreditations and quality standards held by individual STA member companies.

The scheme has received formal recognition from many of the industry’s leading structural warranty and building control bodies: LABC Warranty, Premier Guarantee, Protek Warranty, Build-Zone Warranty, Self-Build Zone Warranty and ABC+ Warranty – as well as the Health and Safety Executive, the National Fire Chief Council (NFCC) and CIREG.

STA Assure mandates members to follow the quality standards put in place by the scheme and offers technical support to enable them to do so:

- Adhere to the Site Safe scheme, ensuring timber construction is both safe and sustainable

- Undergo an independent audit of their quality standards

- Receive regular updates on the latest building regulations and legislation

- Gain access to dedicated technical support service, advice notes and technical documents

- Fully support sustainable construction, quality standards and adhere to our Code of Conduct

- Ensure all installers have met the requirements of STA Timber Frame Competency Award Scheme.

Training

The STA now manages the Timber Frame Competency Award Scheme requirements alongside CITB. The training scheme improves timber frame erectors’ skill levels and acknowledges the competencies of existing timber frame erectors. It supports the achievement of gaining an SVQ or NVQ in Timber Frame Erection, allowing erector/installer companies to access sites that require CSCS cards.

The scheme sets industry-wide standards for erectors and installers of structural timber frames. As part of the STA Assure quality initiative, members are required to complete three workbooks and an online test to examine practical and theory-based knowledge, which takes up to one year to complete.

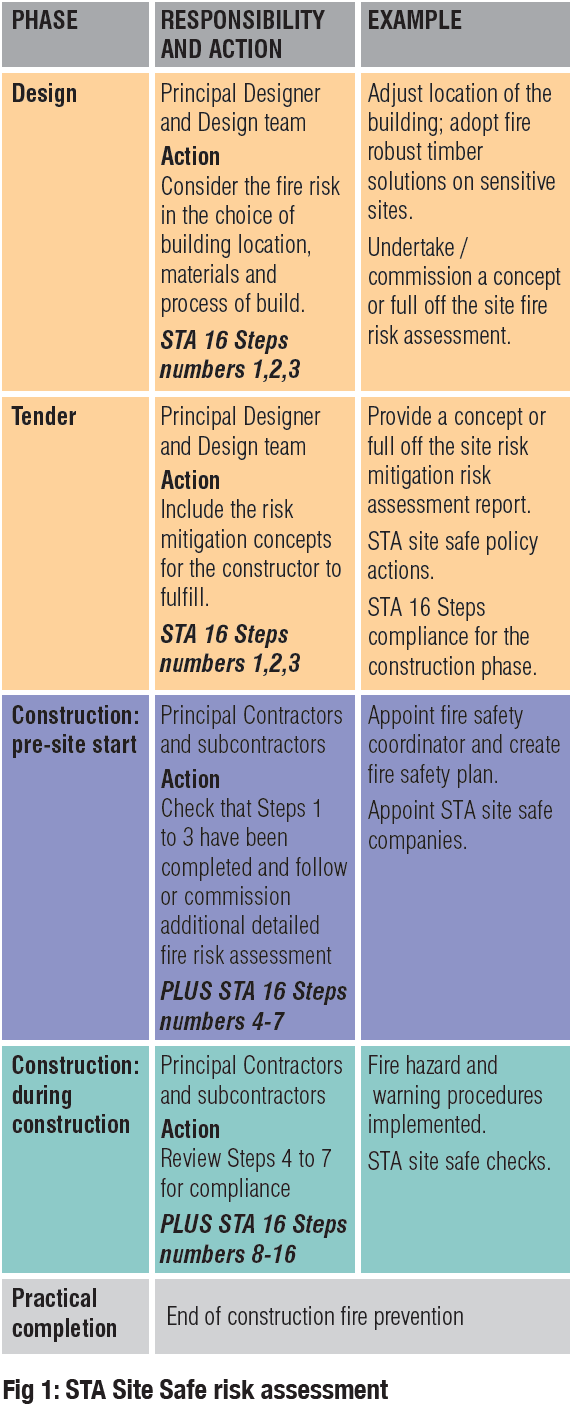

Site Safe policy

The award-winning Site Safe policy applies to all structural timber building system members, including manufacturers, fabricators, contractors and installers who work with principal contractors. Members are audited to ensure they are achieving the functional requirements of the Site Safe policy for sites under construction. Both the policy and the audit process have been developed over many years to support members; by following the policy they can engage with customers and assure the best project outcomes.

Included within members’ Site Safe obligations is a commitment to follow STA 16 Steps. Designed to mitigate the risk of fires during construction, it includes the registration of every STA member on-site construction project with the National Fire Chief Council (NFCC).

The programme is fully endorsed by the Health and Safety Executive and CIREG.

The Structural Timber Association’s insurance industry guide to mass timber in the UK can be downloaded here.